Recognizing the Performance of Membrane Switches for Interface Gadget

The performance of membrane switches over represents a significant development in individual interface style, integrating performance with visual versatility. As industries significantly prioritize individual experience, comprehending the nuances of membrane layer button innovation ends up being essential.

What Are Membrane Layer Switches?

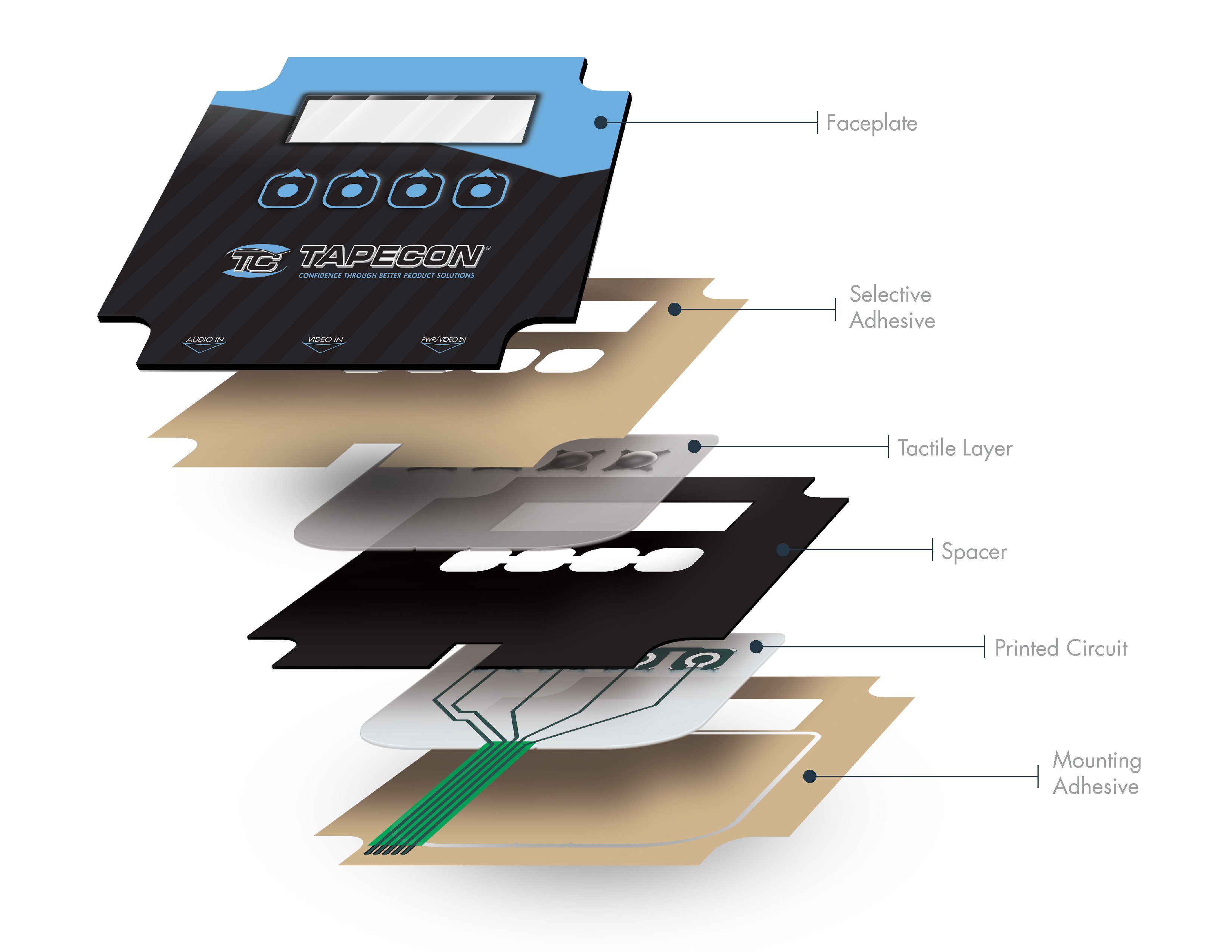

Membrane layer switches are innovative interface tools that help with individual interaction with electronic devices. These flexible elements are composed of multiple layers, consisting of a graphic overlay, spacer, and a published circuit layer. The layout permits for a seamless integration into various electronic tools, enhancing both the aesthetic and useful facets of individual interfaces.

Membrane layer switches are generally employed in a variety of applications, from home home appliances to industrial equipment and clinical tools. Their building and construction normally includes a slim profile, making them a perfect choice for small styles. The responsive comments offered by these buttons can be engineered to fulfill specific individual choices, ensuring efficient interaction in between the customer and the gadget.

Toughness is one more significant benefit of membrane layer buttons, as they are immune to dust, wetness, and chemicals, which boosts their lifespan popular atmospheres. In addition, these buttons can be customized in terms of form, size, and graphic design, permitting branding and user-specific functions. Generally, membrane layer switches stand for a practical option for enhancing customer experience in electronic gadgets, incorporating performance with visual allure in an efficient fashion.

Just How Membrane Layer Switches Over Job

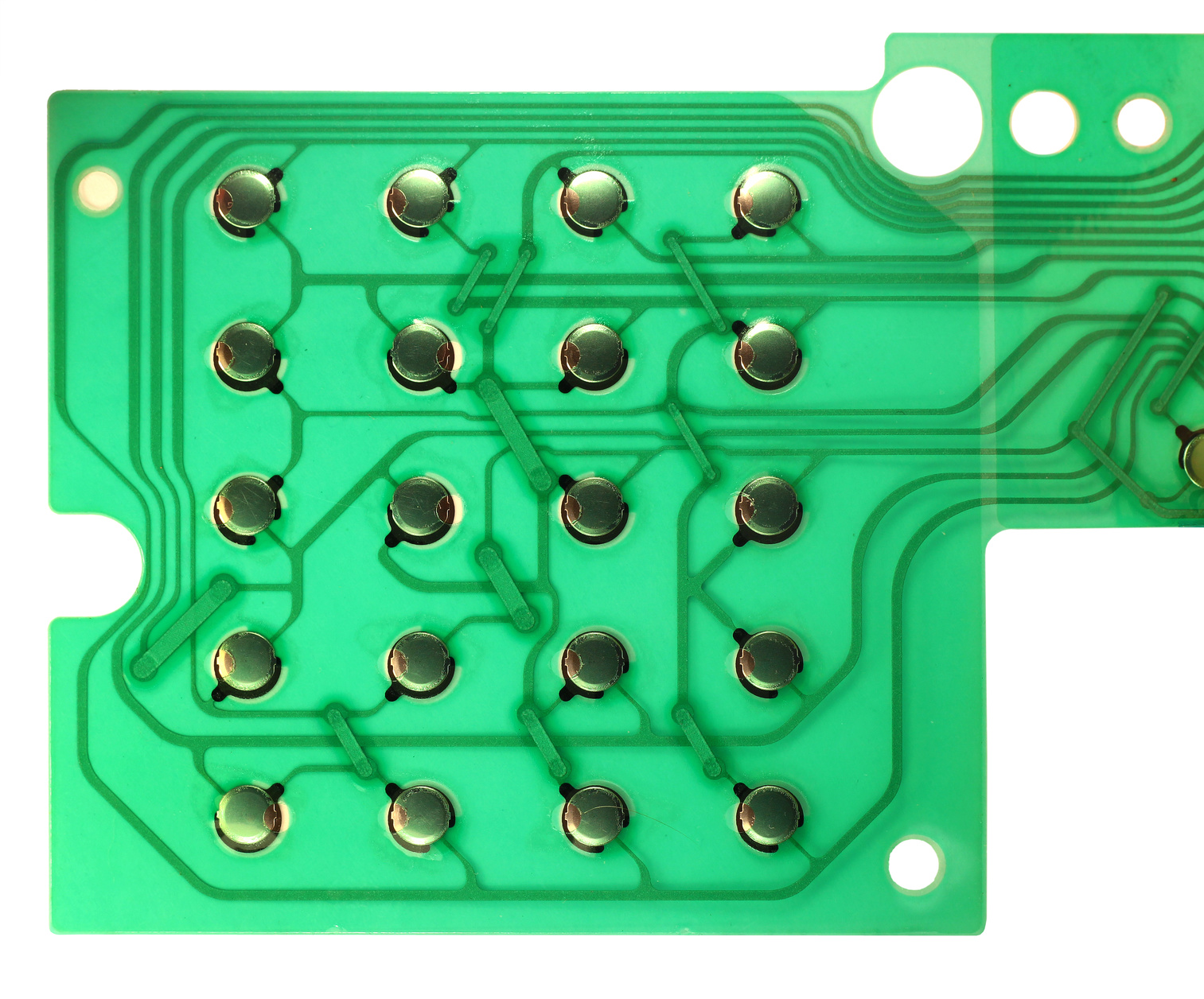

Operating on a simple concept, membrane layer changes make use of a split building and construction to sign up customer input properly. Each button includes several layers, including a published circuit layer, a spacer layer, and a top visuals layer, which are designed to collaborate seamlessly. When a customer presses the top layer, it compresses the spacer layer, bringing the conductive aspects of the circuit layer into call with each various other.

This call produces a closed circuit, signaling the device to implement a certain feature. The layout permits numerous configurations, including responsive responses, which can improve the customer experience by offering a physical feeling upon activation. The products made use of in membrane switches frequently consist of flexible substrates, such as polyester or polycarbonate, which make sure sturdiness and resilience against wear and tear.

Key Advantages of Membrane Switches

One more significant advantage is their compactness. Membrane layer switches are thin and light-weight, which makes it possible for makers to conserve room in their devices without giving up capability. This feature is particularly useful in applications where weight and volume are vital factors to consider.

Furthermore, membrane layer switches are resistant to dust, moisture, and chemicals, improving their resilience. This durability extends their life expectancy click here to read and reduces the requirement for regular substitutes, leading to price financial savings with time.

In addition, the tactile feedback supplied by membrane buttons can be maximized to boost individual communication. They can include features such as increased buttons or distinct clicks, improving use and individual experience.

Applications Throughout Industries

Interface tools making use of membrane layer switches prevail in a wide array of industries, showcasing their flexibility and functionality. Membrane Switch. In the medical field, membrane buttons are important to gadgets such as analysis devices and client monitoring systems, where their durability and simplicity of cleaning are vital for keeping hygiene requirements. In the automobile industry, these buttons are employed in control panel controls and infomercial systems, supplying a smooth and modern-day user interface for individuals.

Furthermore, the customer electronic devices industry benefits from membrane layer switches in appliances and portable gadgets, where compact layout and straightforward interfaces enhance customer experience. Industrial applications also leverage membrane switches over for control board in equipment and automation systems, highlighting their effectiveness and resistance to rough atmospheres.

In the aerospace and protection sectors, membrane buttons are utilized in cockpit controls and tools, where integrity and performance under severe conditions are vital. Additionally, the gaming industry progressively includes membrane buttons in controllers and game machines, adding to an engaging customer experience. On the whole, the adaptability of membrane changes allows their prevalent usage across countless markets, highlighting their relevance in modern interface style.

Future Patterns in Membrane Layer Switch Modern Technology

Furthermore, using advanced materials, such as polycarbonate and polyester films, is expected to increase, providing boosted sturdiness and resistance to environmental stress factors. These page materials contribute to the general longevity of membrane switches, making them ideal for harsher industrial applications.

Furthermore, the incorporation of wise innovation, consisting of IoT connection, will enable membrane layer switches to communicate with various other tools and systems, helping with a much more interactive user experience. This pattern lines up with the expanding demand for smart devices throughout numerous sectors, from health care to customer electronic devices.

Lastly, personalization alternatives are anticipated to broaden, allowing suppliers to develop bespoke solutions tailored to particular individual requirements and preferences. These developments will certainly place membrane layer switches as vital components in the advancement of interface innovation.

Conclusion

In verdict, membrane layer switches over stand for an essential development in customer interface technology, using a reputable and flexible service for varied electronic applications. As innovations in material science and touch picking up innovations continue, the capability and applicability of membrane layer buttons are anticipated to broaden, enhancing their significance in contemporary digital devices.

Comments on “The Duty of a Membrane Switch in Modern Touch Interfaces and Controls”